The best types of shock cords for vibration damping in technical equipment

Vibration can be a serious threat to technical equipment – it can loosen fastenings, misalign components, cause premature wear, and ...

Read full articleDurability, reliability and performance – all are amongst the key requirements that aerospace equipment needs to meet in order to be suitable for operation in highly specialised conditions, and shock cords are no exception. Using them in aircraft, spacecraft, or related environments involves relying on their strength and elasticity to maintain performance across a wide range of stresses. Each component must be engineered with precision to support mission safety and efficiency, with every property working to handle environmental extremes and mechanical demands.

With all our years of experience here at Ibex Ropes Marina, we have a long track record of producing shock cords and assemblies for a wide range of applications in the aerospace sector, so you can count on us to know all about the key requirements they must meet. Here is a brief overview of those requirements.

We will begin with a brief summary of these requirements:

Now to explore these in a little more detail.

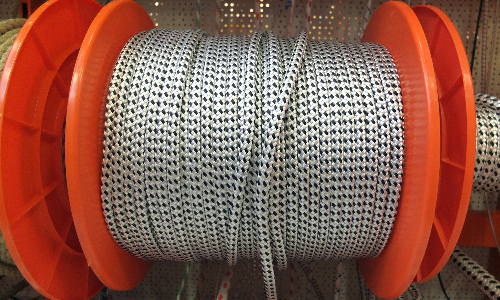

High tensile strength ensures that our shock cords can withstand the operational loads applied in aerospace applications without permanent stretching or failure. For this, we use reinforced core materials and precision braiding techniques that distribute stress evenly across the cord. In flight, this strength keeps equipment firmly secured and maintains the intended level of tension, even during sudden load shifts or turbulence.

Controlled elasticity enables the cord to stretch to a set limit under load and return to its original length without deforming. This reliable performance absorbs shocks and vibrations while preventing excessive movement that could compromise equipment stability. To ensure this elasticity, manufacturers like our team here at Ibex Ropes Marina need to carefully choose elastomer types, adjust core-to-sheath ratios, and set precise production tensions.

Abrasion resistance is a vital requirement because shock cords will often be in contact with fittings, frames, or other surfaces during use. A robust sheath made from tightly woven, abrasion-resistant fibres helps preserve both the strength and elasticity of the core. This means the cord can endure repeated rubbing and friction over long periods without visible wear or loss of performance.

Temperature tolerance ensures that the cord performs across the intense heat of certain aerospace zones and the extreme cold of high-altitude or space environments. The materials for shock cords are chosen for their ability to remain flexible and strong when exposed to both extremes, avoiding brittleness or softening that could reduce effectiveness.

Environmental resilience protects shock cords from degradation due to UV light, moisture, and exposure to chemicals such as fuels and lubricants. Special coatings and resistant fibre types prevent these elements from penetrating or damaging the cord, extending its service life and preserving its mechanical properties.

Material composition directly influences how ours shock cord behave under aerospace conditions. The core typically contains elastomers that determine stretch characteristics, while the sheath provides mechanical protection. If you choose a cord with a high-quality natural or synthetic rubber core, you can expect consistent rebound and tensile behaviour even after repeated stretching in service.

The sheath material is just as important, as it shields the core from mechanical wear and environmental attack. High-performance polyester, nylon, or aramid fibres offer different balances of abrasion resistance, UV stability, and thermal tolerance. For example, polyester sheaths often deliver exceptional resistance to sunlight and general wear, while aramid options provide greater heat tolerance for high-temperature aerospace zones.

Essentially, precision manufacturing ensures that every shock cord meets strict dimensional and mechanical specifications. Consistent braiding patterns and sheath densities ensure that our shock cords perform identically from one length to another, providing reliable performance in critical aerospace applications. Automated quality control systems monitor each stage of production, identifying any inconsistencies in tension, weave, or material quality before cords leave the factory.

Plus, the accurate manufacturing tolerances of our shock cords also ensure their compatibility with aerospace fittings and fasteners. This is vital for maintaining secure connections under vibration, load changes, and environmental stress. Crucially, precision processes prevent defects such as weak points, uneven braids, or inconsistent diameters that could compromise their performance. All this enables them to be integrated into aerospace systems without the risk of unexpected behaviour or reduced service life.

All shock cords that we produce here at Ibex Ropes Marina are subject to rigorous testing processes, to confirm that our shock cords meet aerospace performance and safety standards. Each process targets a specific capability, from strength to environmental durability, so it is ready for demanding operational conditions. This includes:

To explore these in a little more detail…

Tensile testing measures how much load your cord can withstand before failure, ensuring it meets strength requirements. This involves gradually applying force until the cord reaches its limit, confirming it can handle operational stresses.

Elongation testing checks how your cord stretches and recovers under load. It verifies that the cord extends to a set limit and returns to its original length, maintaining stability and consistent shock absorption.

Environmental simulation exposes the cord to heat, cold, UV light, and chemicals to confirm it retains its properties in extreme conditions.

Abrasion testing measures wear resistance by rubbing the cord against surfaces in controlled conditions. Strong results here indicate that the cord can endure prolonged contact without losing performance.

And of course, if you ever need any input or advice about the condition of your shock cords – or any replacements – this is where we can help here at Ibex Ropes Marina. We have unrivalled experience with shock cords, and serve a wide range of sectors across the UK and beyond. As well as the aerospace sector, this also includes military and defence, subsea and offshore, and sport and leisure – just to name a few. If you require any expertise or advice, feel free to give us a call on 01706 360 363, and we will be happy to help however we can.

Vibration can be a serious threat to technical equipment – it can loosen fastenings, misalign components, cause premature wear, and ...

Read full article

Tensile strength ratings are one of the most important specifications you will see when looking at shock cords. Essentially, these ...

Read full article

Here at Ibex Marina Ropes, we are proud to have a long history of supplying a range of sash cords ...

Read full article