What do tensile strength ratings mean for shock cord performance?

Tensile strength ratings are one of the most important specifications you will see when looking at shock cords. Essentially, these ...

Read full articleVibration can be a serious threat to technical equipment – it can loosen fastenings, misalign components, cause premature wear, and interfere with the accuracy and stability of sensitive systems. Shock cords play a vital role in reducing these effects, so whether you are working with instruments that need steady readings, panels that need stability, or machinery that requires secure mounting, you will often find that the right shock cord can make a real difference in how well your setup performs over time. Their ability to repeatedly stretch and return to their original length means that these cords absorb the movement that could otherwise pass directly into delicate parts, keeping everything more stable and reducing wear. This makes them a practical and versatile choice for many applications in technical and industrial environments.

Here at Ibex Ropes Marina, we have extensive experience with providing market-leading shock cords to UK and international customers, so our team have a deep understanding of how they can be used for tamping in technical equipment, especially in sectors like aerospace or the military. Here is a quick overview of how these cords are often used.

First, a quick explanation. Shock cords essentially reduce vibrations by using an elastic core that is able to stretch and take in kinetic energy. When any delicate equipment is exposed to movement from operation, transport, or environmental factors, that movement can travel into the components and create noise, instability, or damage. The elastic core of a shock cord takes on that energy, holding it temporarily and releasing it slowly, so the movement that reaches the equipment is far less severe.

With this in mind, shock cords can be used to support a variety of technical setups. For example, when mounting delicate sensors, the cord’s tension keeps them steady without applying damaging rigid pressure. Control panels or switchboards can be kept in place while still having a degree of movement that prevents cracks or breaks. Enclosures that house precision equipment can benefit from this too, as the cords create a buffer between the equipment and the forces acting on it, whether from machinery vibration, environmental conditions, or handling during relocation.

Natural rubber cords are a primary choice for applications that demand high elasticity and consistent performance. They stretch easily, take in large amounts of movement, and rebound quickly, all of which makes them ideal for reducing the transfer of vibration. This type of cord also maintains a reliable level of stretch even after repeated use, making it well suited to long-term installations. The uniform tension of a natural rubber cord helps to keep equipment stable, as the stretch is smooth and even rather than jerky or uneven.

These cords can be used in a wide range of applications. For example, instrument mounts can be stabilised without making them rigid, which is especially important for equipment that needs precise alignment. Equally, panels in technical machinery can stay secure while still moving enough to absorb shocks, and assemblies with moving parts can have extra support without being restricted. In applications that can often benefit from extra surface protection, hybrid cords with a natural rubber core and a braided or coated outer layer can give the same elastic performance, while also standing up to more wear on the outside.

Some environments expose equipment to high temperatures that could weaken standard cords over time. Heat-resistant shock cords are designed to perform under these conditions by using materials that can handle elevated temperatures without losing elasticity. Silicone cords, for instance, can stay flexible even when exposed to heat for extended periods. Aramid-blend fibres are another option, known for their strength and resistance to both heat and mechanical stress. These materials help to maintain performance in areas where the temperature is a constant factor.

In practical use, these cords are found near engines in industrial or transport equipment, around kilns in manufacturing, or close to heating elements in production machinery. They can protect equipment from vibration while withstanding the heat that would otherwise cause regular cords to degrade. This reliability ensures that even in challenging environments, vital equipment remains stable and supported, reducing the risk of damage caused by constant vibration – especially when combined with high temperatures.

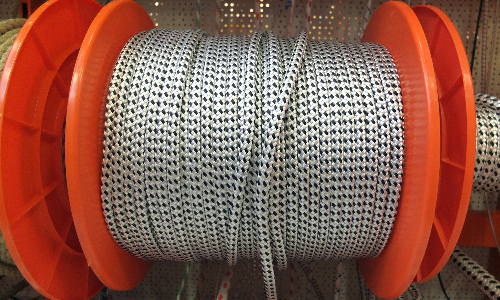

In many technical setups, the cords being used may be in close contact (or permanent contact) with other surfaces that can cause wear over time. To address this, shock cords with abrasion-resistant outer sheaths are often used instead – and this makes up a major part of our offering here at Ibex Ropes Marina. A braided cover made from polyester or nylon creates a protective barrier that stands up to rubbing, scraping, and repeated friction without wearing through quickly. This enables the elastic core inside to keep doing its job.

Applications that benefit from abrasion-resistant shock cords include equipment where the cord moves through pulleys, passes over metal edges, or rubs against moving machinery. In these cases, the outer sheath prevents the cord from fraying or breaking, keeping the system in place and functioning as intended. This durability makes them a good option for long-term installations that need ongoing stability and protection from vibration.

These are all the essential points covered – and if you ever need any help or more specific advice on shock cords and their applications for vibration damping, that is exactly where we can help here at Ibex Marina Ropes. We have unrivalled experience with shock cords, and serve a wide range of sectors across the UK and beyond, including aerospace, military and defence, subsea and offshore, and sport and leisure – just to name a few.

Tensile strength ratings are one of the most important specifications you will see when looking at shock cords. Essentially, these ...

Read full article

Here at Ibex Marina Ropes, we are proud to have a long history of supplying a range of sash cords ...

Read full article

Shock cords are hugely valuable assets, performing a variety of useful roles across multiple key sectors – many of which ...

Read full article